DIE DEVELOPMENT PROCESS

IN-HOUSE TOOLING CAPABILITIES

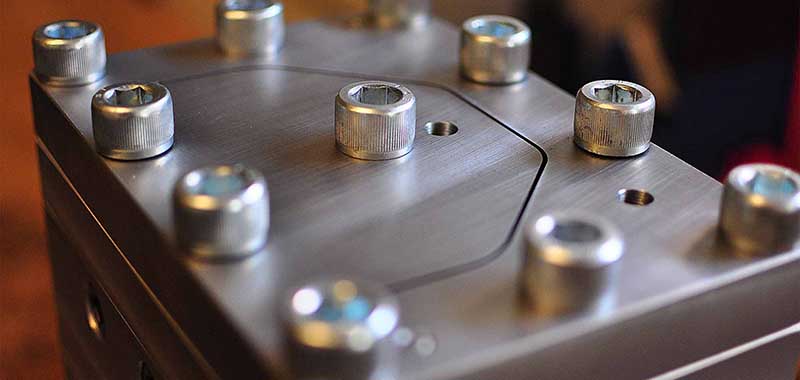

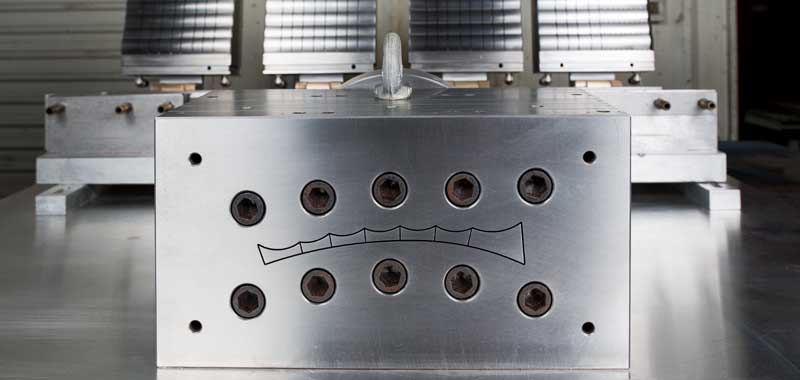

Creating an extrusion process is a intricate and costly engineering endeavor. It involves a multitude of interacting phenomena that are challenging to predict precisely. The flow physics of polymers is particularly sensitive to variations in temperature, pressure, speed, pull force, friction, and the distinct properties of each material type.

The design of custom extrusion tooling depends heavily on an in-depth understanding of the forces involved, accumulated over decades of experience. This knowledge is applied through a disciplined iterative design process. Initially, a die design is crafted and then meticulously modified, incurring significant costs, until a profile can be consistently extruded. This process ensures both economic efficiency and adherence to the exacting specifications demanded by our clients. Trust our seasoned expertise for precision in custom extrusion tooling design.

Employing cutting-edge simulation tools, we analyze the fluid flow characteristics of polymer melts within even the most intricate extrusion dies. Visualizing these results empowers our engineering team to swiftly optimize and iterate on the design of the extrusion dies, significantly expediting product development timelines. Rely on our advanced simulation techniques for rapid and precise extrusion die design.

AGILE MANUFACTURING CAPABILITIES THROUGHOUT NORTH AMERICA

END-TO-END CAPABILITIES

Fabexco manages the process from beginning to end. From initial design and material selection, through die development, manufacturing, finishing, and custom packaging, our ability to control every step in the process enables us to deliver your project on budget, in spec, and on schedule.

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

GET IN TOUCH

LET'S DISCUSS NEXT STEPS

Contact us and we can start the discussion about how to turn your great idea into a market-ready product.

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building Materials

Window & Door

Trucking & Equipment

Light Rail & Transit

Medical

Aerospace

Refrigeration

Material Handling

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building

Materials

Window &

Door

Trucking &

Equipment

Light Rail &

Transit

Medical

Aerospace

Refrigeration

Material

Handling

ENGINEERING REQUIREMENTS

ENGINEERING REQUIREMENTS

OUR HISTORY

OUR HISTORY OUR MISSION, VISION & VALUES

OUR MISSION, VISION & VALUES