CUSTOM

INJECTION MOLDING

Smart Robotics for Precision and Efficiency

Embracing the future of manufacturing, we integrate smart automation into our operations for unmatched precision and efficiency. Our ability to automate production processes ensures consistent quality, reduces turnaround times, and enhances the overall production process. With smart robotics at the core of our operation, we elevate the standard for excellence in injection molding.

Unrivaled Technical Expertise

We have an exceptional team of experts who bring years of hands-on experience to the intricate art of injection molding. Our technical mastery allows us to tackle projects of any complexity, from intricate components to large-scale production. Whatever your vision, our team has the expertise to turn it into reality.

Versatility Across Material Systems

What truly distinguishes us is our versatility in working with a wide array of material systems. Whether it is engineering-grade plastics, elastomers, or specialty polymers, we have the knowledge and capability to handle diverse materials with precision. Our commitment to being at the forefront of material advancements ensures that your projects benefit from the latest innovations.

INJECTION MOLDING

DIFFERENTIATION

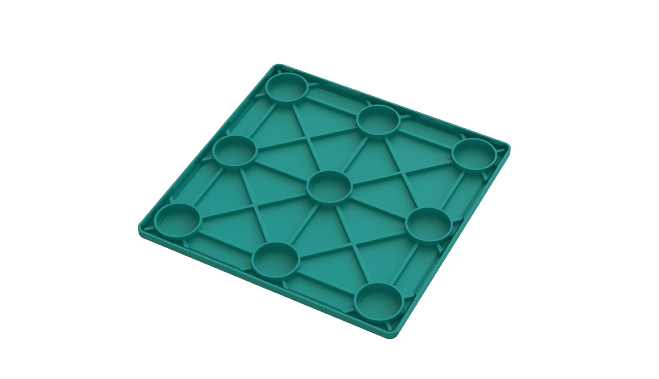

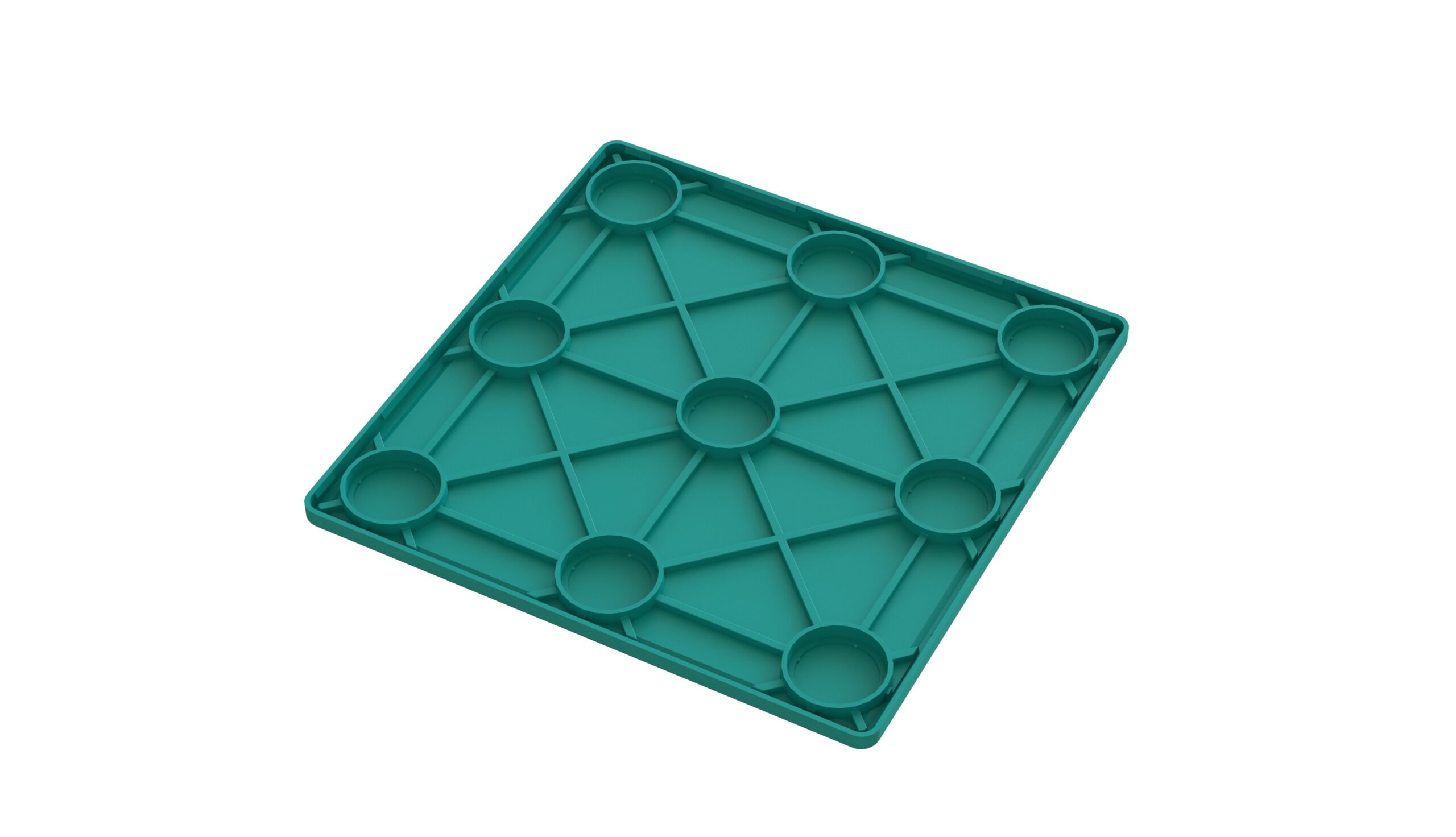

Multi-Cavity Capability

- Multi-cavity Molding for producing high volumes of parts efficiently

- Experience with a variety of multi-cavity mold designs

- Expertise in optimizing multi-cavity molds for cycle time and quality

Large Part Injection Molding

- Injection molding for parts up to 5 pounds

- State-of-the-art equipment for producing large, complex parts

Automated Molding and Processing

- Automated molding and finishing processes for increased efficiency and reduced costs to customer

- End-to-End integration of automation processes for your product

- State-of-the-art robotics for automating all aspects of the injection molding and assembly processes

- Experience with a variety of automated molding and finishing technologies

Optimized Cycle Time

- State-of-the-art capabilities in optimizing cycle time for maximum productivity

- Use of the latest technologies to reduce cycle time without sacrificing quality

- Experience with a variety of cycle time optimization techniques

400 to 660 Ton Press Sizes

- A wide range of press sizes to accommodate parts of all sizes

- State-of-the-art presses with the latest features and capabilities

- Experience with a variety of press sizes and types

INJECTION MOLDING

MATERIALS

- Commodity Polymers: PVC, ABS, HIPS, HDPE, PP

- Engineering Polymers: PC, AMMA

- Recycled Materials: Recycled PVC, ABS, HIPS, HDPE, PP, PC, AMMA

- Biodegradable Plastics: PLA, PHA, PCL

INJECTION MOLDING

SECONDARY OPERATIONS

- Various manual and automated assembly options

- Custom Packaging

- Ultrasonic Welding for large complex parts

INJECTION MOLDING

SECONDARY OPERATIONS

- Various manual and automated assembly options

- Custom Packaging

- Ultrasonic Welding for large complex parts

AGILE MANUFACTURING CAPABILITIES THROUGHOUT NORTH AMERICA

END-TO-END CAPABILITIES

Fabexco manages the process from beginning to end. From initial design and material selection, through die development, manufacturing, finishing, and custom packaging, our ability to control every step in the process enables us to deliver your project on budget, in spec, and on schedule.

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building Materials

Window & Door

Trucking & Equipment

Light Rail & Transit

Medical

Aerospace

Refrigeration

Material Handling

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building

Materials

Window &

Door

Trucking &

Equipment

Light Rail &

Transit

Medical

Aerospace

Refrigeration

Material

Handling

GET IN TOUCH

LET'S DISCUSS NEXT STEPS

Contact us and we can start the discussion about how to turn your great idea into a market-ready product.

ENGINEERING REQUIREMENTS

ENGINEERING REQUIREMENTS

OUR HISTORY

OUR HISTORY OUR MISSION, VISION & VALUES

OUR MISSION, VISION & VALUES