AGILE MANUFACTURING CAPABILITIES THROUGHOUT NORTH AMERICA

END-TO-END CAPABILITIES

Fabexco manages the process from beginning to end. From initial design and material selection, through die development, manufacturing, finishing, and custom packaging, our ability to control every step in the process enables us to deliver your project on budget, in spec, and on schedule.

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

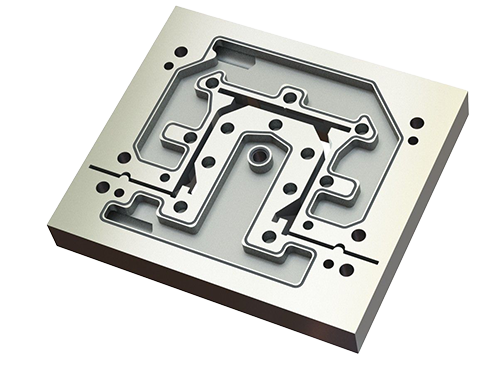

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

Your Great

Idea

Design

Engineering

3D Printed

Prototypes

Material

Selection

Die

Development

Production

Finishing

Operations

Packaging

Solutions

Market Ready

Product

FACILITIES

THROUGHOUT NORTH AMERICA

Fabexco's Manufacturing & Distribution facilities are located throughout the country, ready to serve you - and your customers - wherever needed.

GET IN TOUCH

LET'S DISCUSS NEXT STEPS

Contact us and we can start the discussion about how to turn your great idea into a market-ready product.

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building Materials

Windows & Doors

Trucking & Equipment

Light Rail & Transit

Medical

Aerospace

Refrigeration Gaskets

Material Handling

FABEXCO SERVES MANY DIFFERENT INDUSTRIES INCLUDING

Building

Materials

Windows &

Doors

Trucking &

Equipment

Light Rail &

Transit

Medical

Aerospace

Refrigeration

Gaskets

Material

Handling

KEY INDICATORS

OPERATIONAL FOOTPRINT

Our nationwide footprint, prudence, and forward-thinking approach are ready to power your success. Tell us your vision – we are eager to work with you to turn it into reality.

ENGINEERING REQUIREMENTS

ENGINEERING REQUIREMENTS

OUR HISTORY

OUR HISTORY OUR MISSION, VISION & VALUES

OUR MISSION, VISION & VALUES